In this blog series we will explore the step-by-step instructions to lay the perfect foundation for your sport court and why not all courts cost the same.

Creating a backyard sport court requires careful planning and precise execution to ensure a top-quality playing surface. A couple of the most common questions our Sport Court team receives are:

- Is Sport Court® of Austin a Court Building company or do you just install court surfaces? Yes, Sport Court® of Austin is a comprehensive contractor and has constructed residential and commercial court projects of all sizes. In addition to this written blog post we invite you to watch our YouTube Video where we show step-by-step how we build a backyard Pickleball Court.

2. What will it cost to build a court in my backyard? Several factors impact the final cost of a court. Construction of a court, regardless of size, can directly be impacted by a variety of challenges, known and unknown, depending on the existing site obstacles, soil types and rock formations, local, HOA and/or state building and zoning regulations and the extent of the initial land preparation required.

Prepare the Site:

Before starting any construction, ensure that the site for your court is properly cleared and leveled. Remove any debris, rocks, or vegetation from the area. This initial phase in the process can be the costliest and will consider several factors. For example,

Slope/Grade of the Land:

-

- The slope or grade of the land refers to how steep or gradual the terrain is. It’s essential to assess this when planning construction projects, roadways, or drainage systems.

- Sport Court® Builders consider slope stability, erosion control, and accessibility when designing structures on sloped land.

- The slope or grade of the land refers to how steep or gradual the terrain is. It’s essential to assess this when planning construction projects, roadways, or drainage systems.

Landforms and Elevations:

-

- Landforms encompass natural features such as mountains, valleys, hills, and plateaus. Each landform has unique characteristics and impacts the surrounding environment.

-

- Elevations indicate the height above sea level. Topographic maps display elevation using contour lines, which connect points of equal elevation. Understanding the relationship between landforms and elevations is crucial for site planning, drainage, and infrastructure design.

Excavation and Cut/Fill:

- When preparing a site for construction, excavation may be necessary. Excavation involves removing soil, rock, or other materials.

- Cut and Fill refers to balancing the earthwork. If excess material (cut) is removed during excavation, it can be used to fill (raise) other areas on the site.

- Ideal scenarios for cut and fill:

- Sports Courts: When clearing land for a tennis court, basketball court, or soccer field, cut and fill can create a level playing surface.

- Building Foundations: Adjusting the ground level ensures stable foundations.

- Landscaping: Shaping the land for gardens, ponds, or terraces.

Regulations and Best Practices for Impervious Coverage: It is imperative that you understand the regulations required in your community for impervious covering before starting your project.

Local Zoning Codes: Most communities have regulations governing impervious cover. These codes limit the percentage of a property that can be covered by impermeable surfaces.

What Is Impervious Cover? Impervious cover refers to any surface that prevents water from infiltrating into the ground. These surfaces are impermeable, meaning rainwater cannot seep through.

Common examples of impervious cover include:

- Paved Surfaces: Roads, driveways, sidewalks, and parking lots.

- Concrete or Asphalt: These materials do not allow water penetration.

- Patios and Decks: Solid surfaces that water cannot pass through.

- Remember to consult local authorities and professionals when planning land development. They can guide you on impervious cover limits, sustainable practices, and ways to balance development with environmental stewardship.

Once you have determined if your property meets the impervious cover requirements and that you have the necessary space remaining to construct your court, check your property for other types of property restrictions. Restrictions such as critical root zones, or protected root zones and trees, pool pipes, electrical and cable lines etc. Always call 811 before you dig. The Sport Court® team will help identify potential restrictions and challenges that will need to be addressed before beginning the next phase in the court building process.

After clearing the restrictions and addressing any concerns or potential zoning or code violations, our expert Court Builders will move to the next steps of transforming your backyard space into a sports enthusiast’s dream!

FOUNDATION CONSTRUCTION

The foundation of any court starts with a solid concrete surface.

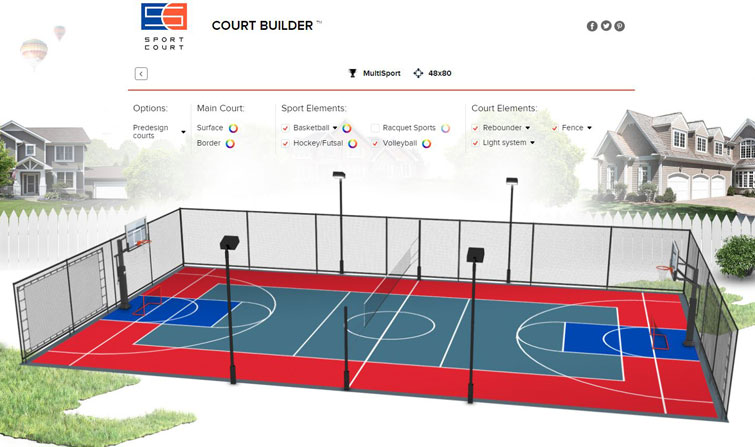

Mark the Court Boundaries:

Using the drawing and the previously developed design documents the team will mark your court boundaries. Using measuring tape and stakes to mark the boundaries of the court, the team will assess and determine that the dimensions meet the official standards of the specific gaming courts you have selected. For maximum versatility, constructing a Multi-Sport Sport Court® allows for basketball, volleyball, pickleball and tennis to be played on one single court using an adjustable net system. Marking the boundaries allows Sport Court Builders and you, as the owner, to visualize the space and area the court will cover once it is installed.

Turndown Beams and Retaining Walls

Some projects require the construction of a retaining wall to support the dirt and concrete used to construct the court. This is determined by the slope and grade of the land where the court will be constructed. Part of the building considerations include designing proper drainage behind a retaining wall. Without allowing for enough space for a court to drain, water will accumulate on and under the court and could result in foundation damage over time.

With a cut and fill technique our Court Builders can move excavated dirt to elevate the lower lying areas for leveling. To contain the dirt a masonry stone or concrete retaining wall is often installed along the scored section of the concrete surface. Many types of walls may be built to suffice this purpose, one of the methods involves the use of a turndown beam. A turndown beam is a sandbag wall that extends from the base of the court to the top of a wooden framed structure. Because this is the lowest part of the court the reenforced rebar, the wooden support wall and hand-filled sandbags will provide a solid surface to fill with concrete, leaving behind a concrete retaining wall when the wooden structure is removed. This will create a strong bond between the concrete and the retaining wall, providing added stability to the court structure.

The wooden structure surrounding the turndown beam must be tall enough to support the dirt, rebar, concrete and turndown beam constructed on the other side. Significant reinforcement is required to support a wooden structure over 4 feet tall. Failing to provide proper support and bracing could result in a concrete blow-out when the wooden structure is removed. Should this happen all of the concrete and materials being contained by the structure will crumble and the concrete work will be ruined. Turndown beams are expensive, but they are less costly than a retaining wall.

Post Tension Cables vs. Rebar Reenforced Foundations

It’s important to confirm and know if a court will be constructed using rebar or post-tension cables. This information should be confirmed with the General Contractor on the project prior to pouring the concrete.

In the context of constructing a sport court, both rebar and post-tension cables can be used to reinforce the concrete slab, depending on factors such as the size of the court, anticipated loads, and engineering requirements. Post-tensioning is often favored for larger courts or those with specific structural demands, as it offers a higher degree of control over cracking and can support larger spans without additional support. However, rebar remains a reliable and commonly used method for reinforcing smaller courts or areas where post-tensioning may not be necessary.

Rebar (Reinforcing Bar):

- Rebar consists of steel bars or mesh placed within the concrete slab before pouring.

- The purpose of rebar is to provide structural strength by resisting tensile forces that may cause the concrete to crack.

- Rebar is typically used in a grid pattern, with bars spaced at regular intervals and intersecting to form a mesh.

- It is essential for preventing cracks and maintaining the structural integrity of the concrete slab over time.

Post-Tension Cables:

- Post-tensioning involves placing high-strength steel cables or tendons within the concrete slab after it has been poured and partially cured.

- These cables are then tensioned using hydraulic jacks, applying compressive forces to the concrete.

- The purpose of post-tensioning is to improve the concrete’s strength and reduce cracking by creating a pre-stressed structure that can better withstand tensile forces.

- Post-tensioning is often used in larger concrete structures or where longer spans are required, as it allows for more significant structural support without adding excessive weight.

Begin by pouring concrete within the marked boundaries of your court and level it evenly. It’s crucial to ensure that the concrete is set but not fully cured before proceeding to the next step. Once the concrete is at the right stage, apply a light broom finish. This finish creates a textured surface with small grooves that serve two important purposes. Firstly, it aids in water drainage, preventing puddles and ensuring a dry playing surface. Secondly, it provides traction for players, reducing the risk of slips and falls during intense matches.

- Pro Tip – Score the Last Six Inches to enhance the adhesion of the masonry stone retaining wall, using a scoring tool to create shallow grooves in the concrete surface. These scores will provide a better surface for the retaining wall to adhere to, ensuring its stability and longevity.

Complete Concrete Work:

Once the concrete is poured our team will check the court to ensure the surface is even and that there are no low or high spots. This is to prevent inconsistencies in ball response as well as eliminate areas where water may pool on the court. Once the court dries the installers will lightly sweep the surface with a broom to clean out the grooves for optimal traction and grip to hold the acrylic surface in place. It is also at this time that we set the fence posts inside the concrete in PVC sleeves. This allows for easy removal during fence installation.

Once the concrete has time to set, our court builders inspect the fidelity of the structure to ensure that the footing for the masonry retaining wall will securely be integrated into the court to withstand the rigors of play.

Pickleball court construction requires significant planning and preparation. DIY courts are always an option, but unless you have concrete foundation experience, constructing a turndown beam or retention wall we highly recommend hiring professionals. The quality of the court foundation will directly impact your future of play and pickleball happiness.